We spread food safety awareness such as FSMS ,HACCP, ISO 22000, GHP, SOPs and daily updates on food safety.

*IMPORTANT MEDICAL NUMBERS IN THE LIFE OF EVERY HUMAN BEING*

Blueberries😋

It has been seen that anthocyanins works much better than other flavonoids to keep your blood pressure low.

➡➡➡➡➡#Health benefits of bluberries :

1) Boost immunity .

2)Help prevent UTI.

3)Lower Risk of heart disease.

4) Supports healthy blood pressure.

5)makes memory sharp .

6)Protects the brain.

7)Full of vitamins anf fiber .

8) Antioxidants properties.

9)improve eye vision.

10)Good for digestive tract.

Thank you 💕☺️💕

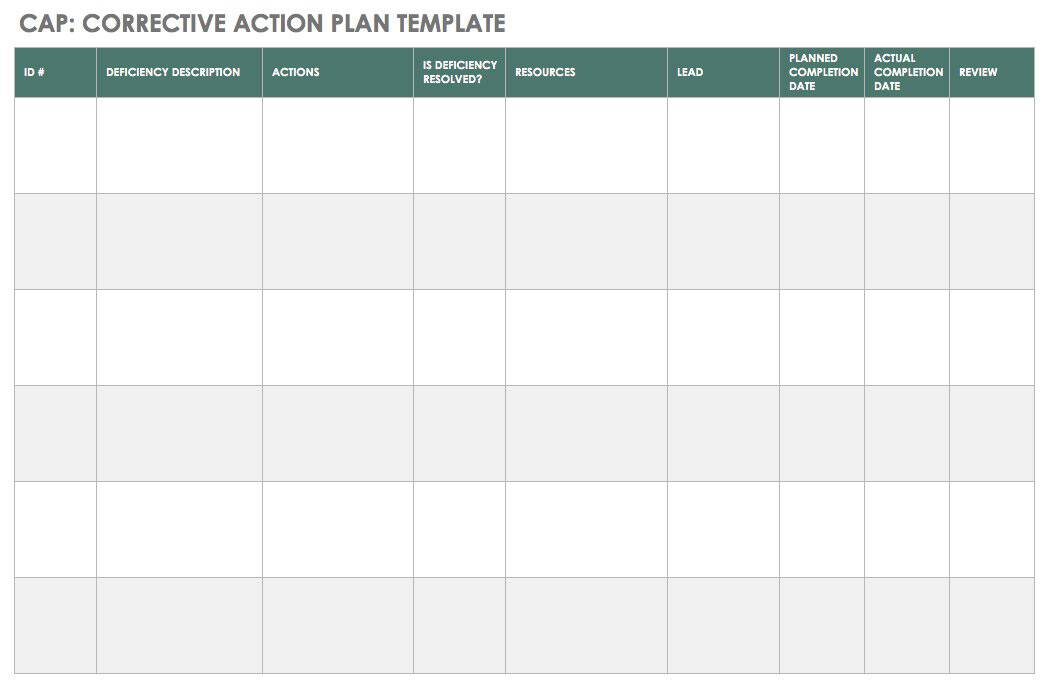

CAPA - corrective action and preventive action

What Is CAPA?

Ø CAPA is the abbreviation for corrective action and preventive action. These two aspects of CAPA have traditionally been connected, but are ideally are only distantly related. Here is the main difference between the two:

Ø Corrective Action:

Elimination of the cause or causes of an existing nonconformity or undesirable situation in order to prevent recurrence.

Ø Preventive Action:

Identification and elimination of the cause(s) of potential non-conformities in order to prevent occurrence.

Ø In standards such as ISO 9000 and FDA 21 CFR 820, the description of preventive action follows directly after the description of corrective action, which has led to the misconception that the two processes must work together in series. In fact, they are separate, and preventive action ideally precedes corrective action to prevent or avoid the need for corrective action.

Ø CAPA processes are used particularly in food processing, medical device development and manufacturing, and pharmaceuticals. FDA 21 CFR 820 is the quality system regulation that requires corrective and preventive procedures to be documented in medical device manufacturing facilities.

Ø Corrective and preventive actions also have a place in the quality management process as defined in the Project Management Book of Knowledge (PMBOK). Corrective and preventive action is also considered a tool within Six Sigma for understanding regular business operations. CAPA has strong parallels with Design for Six Sigma (DFSS), used to design new products or redesign existing products. The analytical aspects of both corrective and preventive actions also harken back to PDCA.

What Is a CAPA Report?

A CAPA report provides a consistent vehicle for recording defects and issues as well as the method of their correction. Usual details include where the problem occurred, the customer’s name and address, the details of the problem, whether there was a product breakdown, whether there was an injury, and so on. The report also states what immediate action or correction was taken. The report may walk you through the process, suggest tools for the root cause analysis (such as 5 Whys and cause and effect analysis), and provide room to record analysis results. It may also provide guidance on how to route the report depending on the outcome of the analysis.

You can use the free template below to create a CAPA report.

How to Read an NFPA Fire Diamond (chemical, fire, health and instability hazard)

How to Read an NFPA-704 Fire Diamond - (National Fire Protection Association)

What is NFPA 704

NFPA -704 is also known as the “Standard System for the Identification of the Hazards of Materials for Emergency Response.” In other words, it’s the codes and standards that rule how hazardous materials need to be marked. In order to regulate this, the National Fire Protection Association created and standardized the NFPA Fire Diamond – also known as the “safety square.” This icon allows for quick and easy identification of the risks linked to various hazardous materials.

What is NFPA 704

NFPA is also known as the “Standard System for the Identification of the Hazards of Materials for Emergency Response.” In other words, it’s the codes and standards that rule how hazardous materials need to be marked. In order to regulate this, the National Fire Protection Association created and standardized the NFPA Fire Diamond – also known as the “safety square.” This icon allows for quick and easy identification of the risks linked to various hazardous materials.

The image shown above displays an example of a Fire Diamond along with quick reference guide on how to read each section.

Reading an NFPA Fire Diamond

Here’s everything you need to know when assessing an NFPA Fire Diamond:

Yellow Definitions

The yellow section of an NFPA Fire Diamond is used to assess a material’s instability.

0 = Stable

1 = Unstable if heated

2 = Violent chemical change

3 = Shock and heat may detonate

4 = May detonate

Red Definitions

The red section of an NFPA Fire Diamond is used to assess a material’s flammability.

0 = Will not burn

1 = Above 200°F

2 = Below 200°F

3 = Below 100°F

4 = Below 73°F

Blue Definitions

The blue section of an NFPA Fire Diamond is used to assess a material’s health hazard.

0 = Normal material

1 = Slightly hazardous

2 = Hazardous

3 = Extreme danger

4 = Deadly

White Definitions

The white section of an NFPA Fire Diamond is used to assess a material’s specific and special hazards. This section differs from the other three as it uses symbols to display specific hazards.

ACID = Acid

ALK = Alkali

COR = Corrosive

OX = Oxidizer

☢ = Radiation hazard

-W- = Do not use water

Thank you..

The Bio Helper Cell...........

A Healthy Plate 🥗🍲🍛🍜

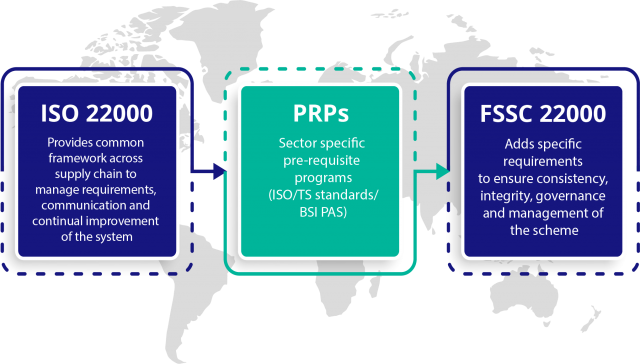

ISO22000 VS FSSC 22000A

ISO22000 VS FSSC 22000A

About FSSC 22000A

It is an ISO-based scheme monitoring the quality of food products of the food and beverage manufacturing sectors. It consists of three main components namely Food and feeds for animals as per ISO-22002-6 clause, food packaging and manufacturing according to clause ISO 22002-3, and Retail and Supermarkets.

The food and packaging manufacturers should follow guidelines whilst manufacturing food products. Apart from producing safe and hazard-free products, they should implement an effective waste management system, water disposal system, prevent cross-contamination, provide pest control services, maintain proper warehousing systems, etc to ensure overall safety to the workers and members of the organizations.

About ISO 22000 certification

It is an international framework specifying guidelines to the food management system The organizations should implement necessary mechanisms to manage the safety of the food products and services.

To obtain ISO 22000 certification, the organizations should perform some important procedures such as building a risk-based system to monitor the risks involved from the stage of production to distribution, implementing hazard control plans, communicating information to the concerned parties, and continuously striving to improve food quality.

Learn the Difference between FSSC 22000 and ISO 22000 certification

|

FSSC 22000 Certification |

ISO 22000 Certification |

|

To obtain FSSC 22000 certification, the organizations should follow the Pr-Requisite Program or some additional procedures that are globally accepted to ensure the food quality products to the customers. |

FSSC 22000 is a framework based upon the principles of ISO 22000 but the procedure of ISO 22000 certification is shorter. |

|

To obtain FSSC 22000 certification you should fulfill ISO 22000: 2018, FSSC 22000 Part I and ISO/TS 22001-1, or ISO/TS 22001-4 programs. |

To obtain ISO certification in India, you should only produce ISO 22000: 2018 and ISO/TS 22001-1 or ISO/TS 22001-4 programs. |

|

The FSSC 22000 clause defines how to implement a Pr-requisite program. |

Although you should perform the PRP procedure for ISO 22000 certification, it does not mention the ways of implementing PRP |

|

The FSSC 22000 is only applicable to some industries such as food packaging, agricultural, catering, and food processing industries. |

This certificate is provided to different types of organizations whether big or small such as warehousing, storage operators, food outlets, retail industries, contractors, etc. |

|

The FSSC 22000 covers only the managerial aspect of food production and distribution |

The ISO 22000 includes the managerial aspects and HACCP (Hazard Analysis Critical Control Point) |

Conclusion

Both the Certificates state about the food management practices to ensure quality food products to the consumers. Any organization within its food chain can obtain an ISO 22000 certificate, but the FSSC 22000 certificate is obtained by some industries. The procedure to obtain FSSC 22000 certificate is lengthier. Therefore, you must first try to achieve ISO 22000 Certification.

Heart Attack Symptoms, Risk, and Recovery..... ــــــــــﮩ٨ـ❤️ﮩ٨ـﮩﮩ٨ـ💔

What is a heart attack? A heart attack, also called a myocardial infarction, happens when a part of the heart muscle doesn’t get e...

-

12 Steps of HACCP 1. Assemble and train the HACCP team The HACCP team must be proportionate to the size, risk and complexity of the bu...

-

personal hygiene Good personal hygiene involves keeping all parts of the external body clean and healthy. It is important for maintaining...

-

Food Temperature for food products Meat temperatures Poultry 74°C ...